Wholesale Square Pipe Making Line - High reputation China Automatic Pipe Welding Machine with Orbital External Pipe Welding for Tube to Tube Welding – TUBO Detail:

Our eternal pursuits are the attitude of “regard the market, regard the custom, regard the science” as well as theory of “quality the basic, have faith in the initial and administration the advanced” for High reputation China Automatic Pipe Welding Machine with Orbital External Pipe Welding for Tube to Tube Welding, Be sure to deliver us your specifications and requirements, or experience totally free to get in touch with us with any questions or inquiries that you may have.

Our eternal pursuits are the attitude of “regard the market, regard the custom, regard the science” as well as theory of “quality the basic, have faith in the initial and administration the advanced” for Automatic Weldingmachine for Pipeline, China Orbital Welding Machine for Pipeline Project, Our company is continuing to serve customers with high quality, competitive price and timely delivery. We sincerely welcome friends from all over the world to cooperate with us and enlarge our business. If you are interested in our products, you should feel free to contact us. We would love to offer you with further information.

Production description

ERW219 Tube mill/pipe mill/welded pipe production/Pipe making machine is used to Produce steel pipes of 89mm~219mm in OD and 2.0mm~8.0mm in wall thickness, as well as corresponding square and rerctangular pipe.

Application:GI,Construction,Automotive,General Mechanical tubing,Furniture, Agriculture,Chemistry,Oil,Gas, Conduit,Contructure.

|

Product |

ERW219mm Tube Mill |

|

Applicable Material |

HR/CR,Low Carbon Steel Strip Coil ,Q235,S235,Gi Strips. σb≤550Mpa,σs≤235MPa |

|

Pipe cutting Length |

60.~12.0m |

|

Length Tolerance |

±1.5mm |

|

Surface |

With Zinc Coating or without |

|

Speed |

Max. Speed : ≤120m/min (can customized according to customer’s requirements) |

|

Others |

All the pipe is high frequency welded |

|

Material of roller |

Cr12 |

|

Squeeze roll |

H13 |

|

Scope of Pipe Making Machine |

Hydraulic double-Mandrel un-coiler |

|

All auxiliary equipment and accessories, such as uncoiler, motor, bearing, cutting saw, roller, hf, etc., All are top brands. The quality can be guaranteed. |

|

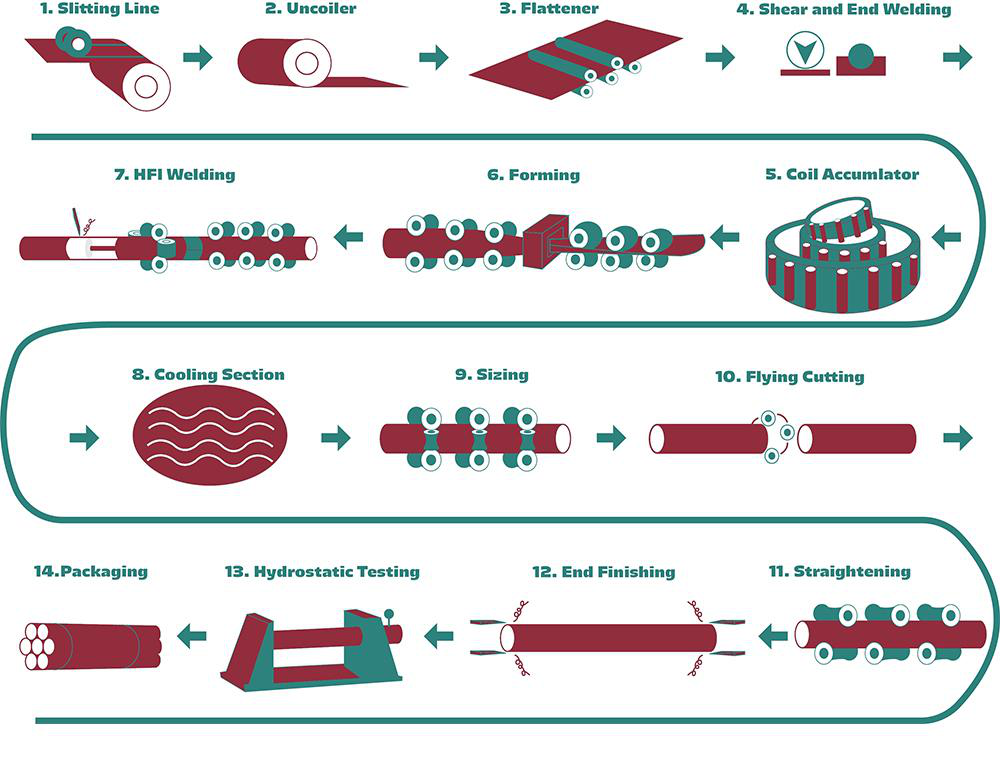

Process Flow

Steel Coil → Double-arm Uncoiler → Shear and End Cutting & Welding → Coil Accumulator → Forming (Flattening Unit + Main Driving Unit + Forming Unit + Guide Unit + High Frequency Induction Welding Unit + Squeeze Roller) → Deburring → Water Cooling → Sizing & Straightening → Flying Saw Cutting → Pipe Conveyor → Packaging → Warehouse Storage

Advantages

1.High Precision

2.High Production efficiency,Line speed can be up to 120m/min

3.High Strength,The machine works stably at a high speed, which improves product quality.

4.High Good product rate, reach to 96.5%

5.Low wastage, Low unit wastage and low production cost.

Specification

|

Raw Material |

Coil Material |

Low Carbon Steel, Q235, Q195 |

|

Width |

280mm-690mm |

|

|

Thickness: |

2.0mm-8.0mm |

|

|

Coil ID |

Φ580-φ630mm |

|

|

Coil OD |

Max φ2000mm |

|

|

Coil Weight |

15Tons |

|

|

Production Capacity |

Round Pipe |

89mm – 219mm |

|

Square & Rectangular Pipe |

70*70mm - 170*170mm |

|

|

Wall Thickness |

2.0- 8.0mm (Round Pipe) |

|

|

Speed |

Max. 50m/min |

|

|

Pipe Length |

5m – 12m |

|

|

Workshop Condition |

Dynamic Power |

380V, 3-phase, 50Hz (depends on local facilities) |

|

Control Power |

220V, single-phase, 50 Hz |

|

|

Size of the whole line |

100m X 9m (L*W) |

|

Product Range

| - Material | HRC, CRC, Galvanized Steel |

| - Type | Round, Square & Rectangular pipe |

| - Round Tube | 89mm – 219mm |

| - Square Tube | 70 x 70 – 200 x 200mm |

| - Rectangular Tube | 70 x 80 – 200 x 180mm |

| - Wall thickness | 2.0 mm – 8.0 mm |

| - Pipe length | 6.0m – 12.0m |

| - Line Speed | Max. 50 m/min |

| - Welding Method | GGP600kW Solid State High Frequency Welding |

| - Forming Method | Conventional Forming; FFX Forming |

| - Cutting Type | Friction Saw or Orbital Cutting(Cold Saw) |

| - Installation Electric Capacity | Approx:1100Kw |

We always design and make each line according to each customer’s specific requirements, so each customer can buy his own well-content line from us.

For more information, please send us inquiry.we are tube mill manufacturer and tube mill supplier ,you can know it.Our eternal pursuits are the attitude of “regard the market, regard the custom, regard the science” as well as theory of “quality the basic, have faith in the initial and administration the advanced” for High reputation China Automatic Pipe Welding Machine with Orbital External Pipe Welding for Tube to Tube Welding, Be sure to deliver us your specifications and requirements, or experience totally free to get in touch with us with any questions or inquiries that you may have.

High reputation China Orbital Welding Machine for Pipeline Project, Automatic Weldingmachine for Pipeline, Our company is continuing to serve customers with high quality, competitive price and timely delivery. We sincerely welcome friends from all over the world to cooperate with us and enlarge our business. If you are interested in our products, you should feel free to contact us. We would love to offer you with further information.

Product detail pictures:

Related Product Guide:

We take pleasure in an extremely fantastic standing among the our prospects for our great product top quality, competitive cost and the finest support for Wholesale Square Pipe Making Line - High reputation China Automatic Pipe Welding Machine with Orbital External Pipe Welding for Tube to Tube Welding – TUBO , The product will supply to all over the world, such as: Angola, Mombasa, Detroit, They're durable modeling and promoting effectively all over the world. Under no circumstances disappearing major functions in a quick time, it's a should for you of excellent good quality. Guided by the principle of "Prudence, Efficiency, Union and Innovation. the company make a terrific efforts to expand its international trade, raise its company profit and raise its export scale. We're confident that we are going to possess a vibrant prospect and to be distributed all over the world within the years to come.

1. Q : Are you manufacturer ?

A: Yes, We are manufacturer . More than 15 years R&D and Manufacturing Experience. We use more than 130 CNC machining equipments to guarantee our products perfect.

2. Q: What payment terms do you accept?

A: We are flexible on payment terms, please contact us for details.

3. Q:What information do you need to supply a quotation?

A: 1. Maximum Yield Strength of the material,

2.All pipe sizes needed (in mm),

3. Wall thickness (min-max)

4. Q: What is your advantages?

A: 1. Advanced mould share-use technology (FFX, Direct Forming Square). It saves a lot of invest amount.

2. Latest quick change technology to increase the output and reduce labor intensity.

3. More than 15 years R&D and Manufacturing Experience.

4. 130 CNC machining equipments to guarantee our products perfect.

5. Customized According to Customer Requirements.

5. Q: Do you have after sales support?

A: Yes,we have. We have a 10-person -professional and strong installation team.

6.Q: How about your service?

A:(1) One year’s warranty.

(2) Providing spare parts for life time at cost price.

(3) Providing Video technical support, Field installation, commissioning and training, online support, Engineers available to service machinery overseas.

(4) Provide technical service for facility reforming, refurbishment.

The product classification is very detailed that can be very accurate to meet our demand, a professional wholesaler.