Production Description

This equipment is specially used for producing high-frequency straight seam welded pipe and corresponding square pipe and special-shaped pipe. The composition of equipment is from uncoiler to fixed length cutting saw .Rolling speed can be ajusted correspondingly within suitable range of pipe diameter and wall thickness.

|

Product |

Welded Pipe Machine |

|

Applicable Material |

HR/CR,Low Carbon Steel Strip Coil ,Q235,S235,Gi Strips. σb≤550Mpa,σs≤235MPa |

|

Pipe cutting Length |

60.~12.0m |

|

Length Tolerance |

±1.5mm |

|

Surface |

With Zinc Coating or without |

|

Speed |

Max. Speed : ≤120m/min (can customized according to customer's requirements) |

|

Others |

All the pipe is high frequency welded |

|

Material of roller |

Cr12 |

|

Squeeze roll |

H13 |

|

Scope of welded pipe equipment |

Hydraulic double-Mandrel un-coiler |

Application:GI,Construction,Automotive,General Mechanical tubing,Furniture, Agriculture,Chemistry,Oil,Gas, Conduit,Contructure.

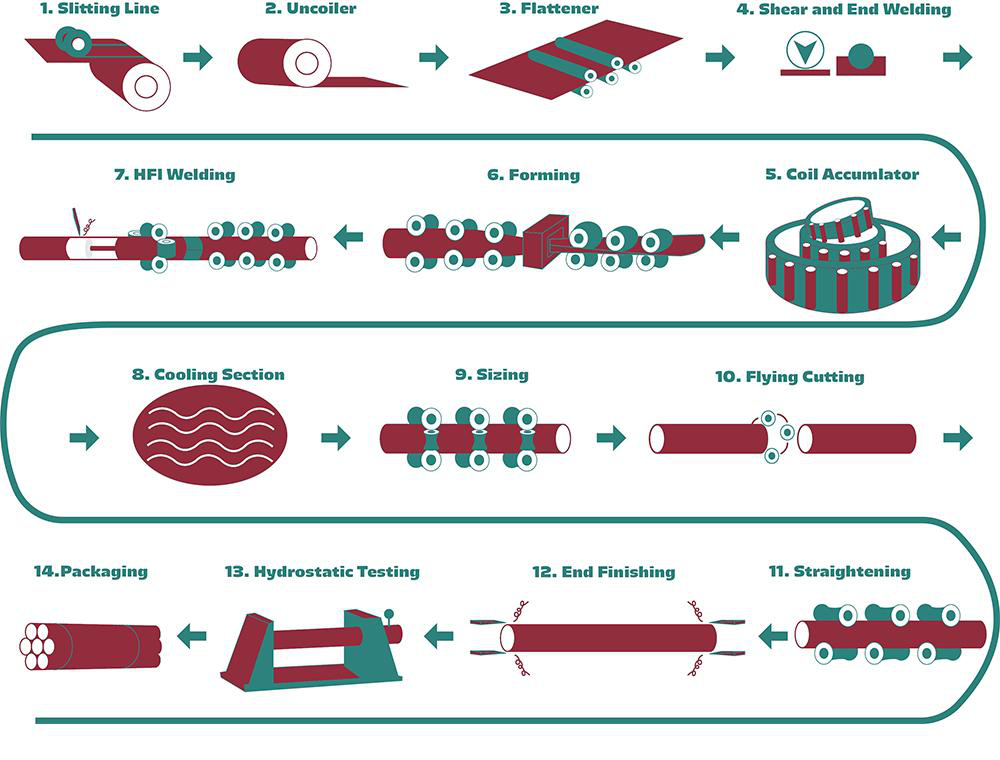

Process Flow

Steel Coil → Double-arm Uncoiler → Shear and End Cutting & Welding → Coil Accumulator → Forming (Flattening Unit + Main Driving Unit + Forming Unit + Guide Unit + High Frequency Induction Welding Unit + Squeeze Roller) → Deburring → Water Cooling → Sizing & Straightening → Flying Saw Cutting → Pipe Conveyor → Packaging → Warehouse Storage

Advantage

1.High Production Efficiency.

2.High precision

3.High Strength,The machine works stably at a high speed, which Improves product quality.

4.Low Defective product rat

5.Save Roller Chaning Time

6.Save invetment on rollers

Specification

|

Raw Material |

Coil Material |

Low Carbon Steel, Q235, Q195 |

|

Width |

35mm-120mm |

|

|

Thickness |

0.5mm-2.5mm |

|

|

Coil ID |

φ450-φ520mm |

|

|

Coil OD |

Max φ1200mm |

|

|

Coil Weight |

1.0-1.5Tons |

|

|

Production Capacity |

Round Pipe |

8mm - 32mm |

|

Square & Rectangular Pipe |

8*8 - 25*25mm |

|

|

Wall Thickness |

0.5 - 2.0mm (Round Pipe) |

|

|

Speed |

Max. 120m/min |

|

|

Pipe Length |

3m – 12m |

|

|

Workshop Condition |

Dynamic Power |

380V, 3-phase, 50Hz (depends on local facilities) |

|

Control Power |

220V, single-phase, 50 Hz |

|

|

Size of the whole line |

50m X 5m (L*W) |

|

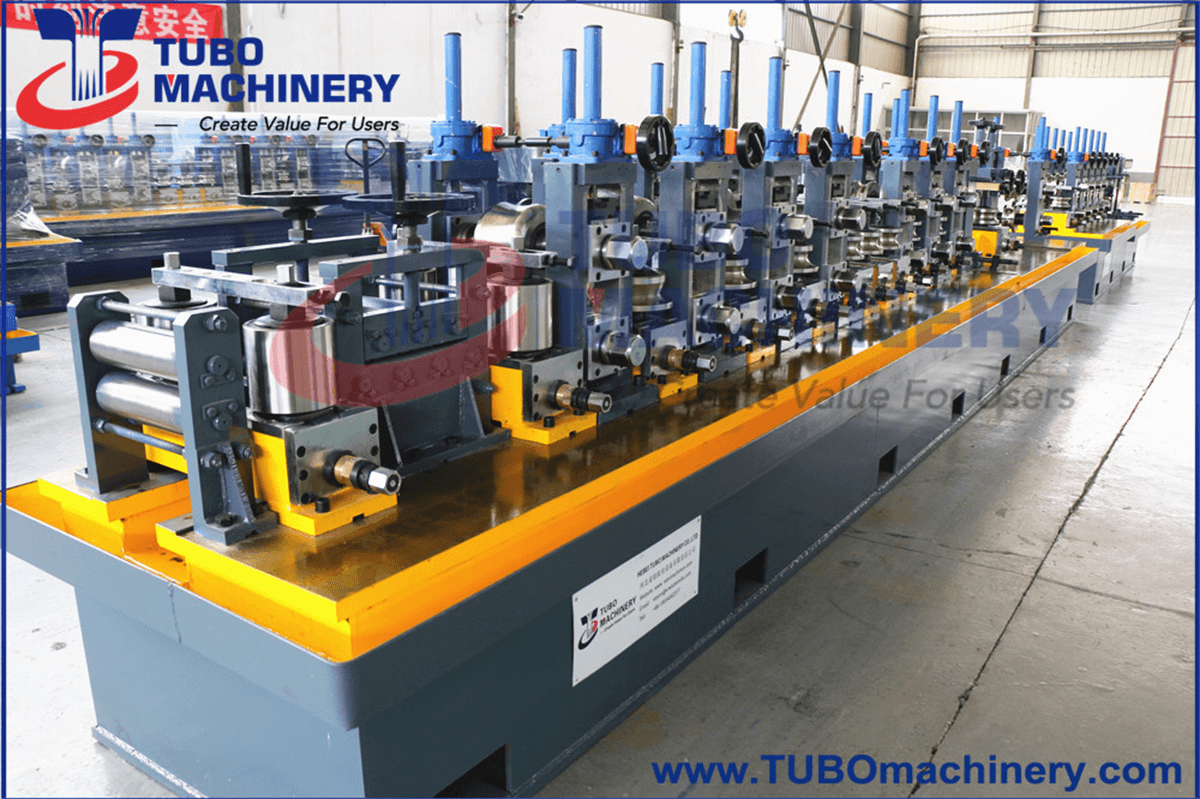

Company Introduction

Hebei Tubo Machinery Co.,LTD is a high-tech enterprise registered in Shijiazhuang City. Hebei Province. It specialized in Developing and Manufacturing for the complete set of equipments and related technical service of High Frequency Welded Pipe Production Line and Large-size Square Tube Cold Forming Line .

Hebei Tubo Machinery Co.,LTD With more than 130 sets all types of CNC machining equipment, Hebei Tubo Machinery Co.,Ltd., manufactures and exported to over 15 countries of welded tube/pipe mill, cold roll forming machine and slitting line, as well as auxiliary equipment for more than 15 years.

TUBO Machinery, as a partner of users, provides not only high precision machine products, but also technical support everywhere & anytime.

Our Workshop

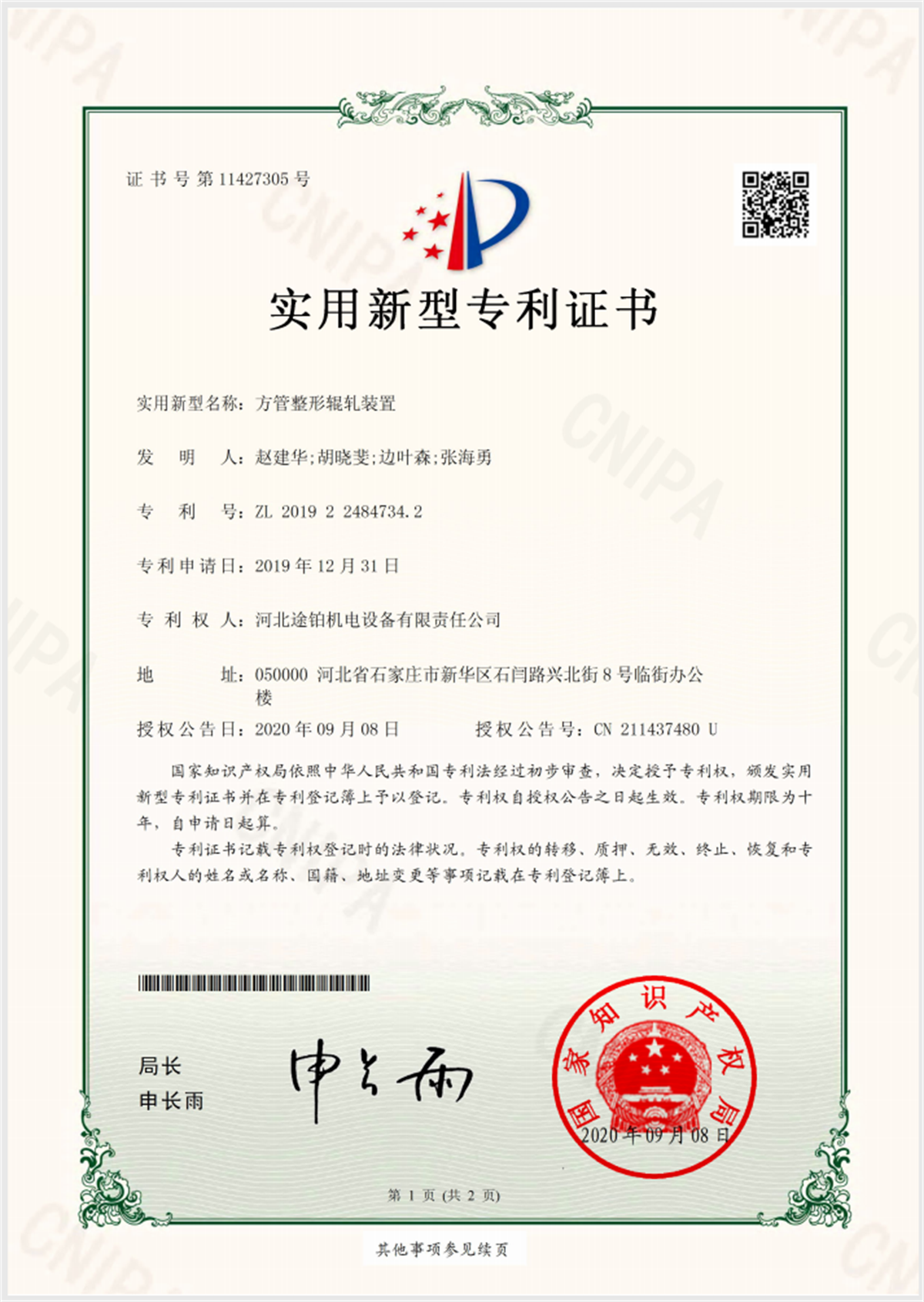

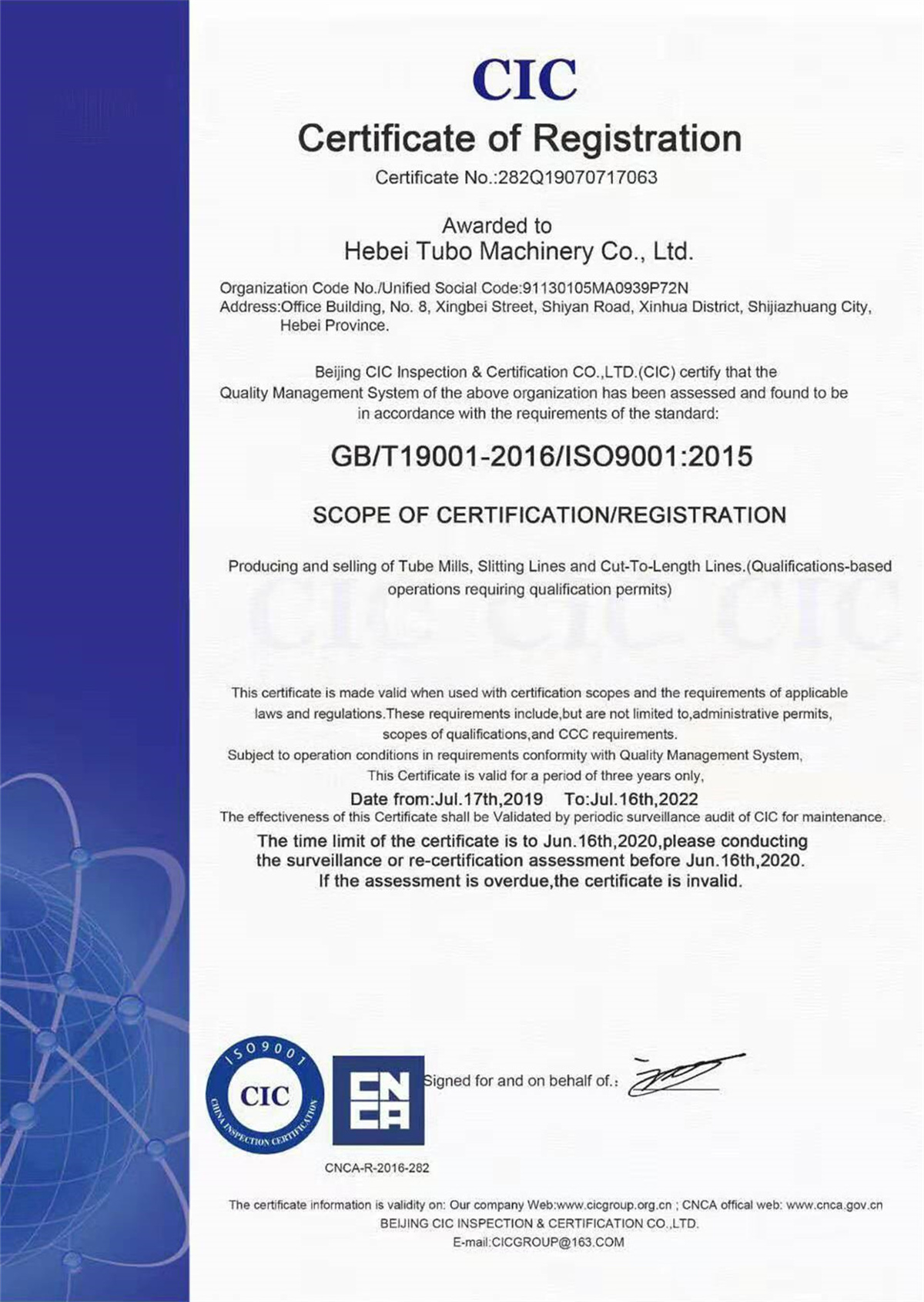

Our Certificate

Field Visits

Our advantage

1)We have our own CNC Machining Center, We can control cost and deliverly time.

2) More than 15 years R&D and Manufacturer Experience.

3) We can customized according to customer’s requirements.

4) We have professional researching, designing, processing, testing and after-sale service teams.

5) We can Strict quality control in raw material, processing accuracy,heat treatment,assembling accuracy,standard components and so on. Strict inspection for equipment before delivery.

Packing&shipping

1. Q : Are you manufacturer ?

A: Yes, We are manufacturer . More than 15 years R&D and Manufacturing Experience. We use more than 130 CNC machining equipments to guarantee our products perfect.

2. Q: What payment terms do you accept?

A: We are flexible on payment terms, please contact us for details.

3. Q:What information do you need to supply a quotation?

A: 1. Maximum Yield Strength of the material,

2.All pipe sizes needed (in mm),

3. Wall thickness (min-max)

4. Q: What is your advantages?

A: 1. Advanced mould share-use technology (FFX, Direct Forming Square). It saves a lot of invest amount.

2. Latest quick change technology to increase the output and reduce labor intensity.

3. More than 15 years R&D and Manufacturing Experience.

4. 130 CNC machining equipments to guarantee our products perfect.

5. Customized According to Customer Requirements.

5. Q: Do you have after sales support?

A: Yes,we have. We have a 10-person -professional and strong installation team.

6.Q: How about your service?

A:(1) One year’s warranty.

(2) Providing spare parts for life time at cost price.

(3) Providing Video technical support, Field installation, commissioning and training, online support, Engineers available to service machinery overseas.

(4) Provide technical service for facility reforming, refurbishment.