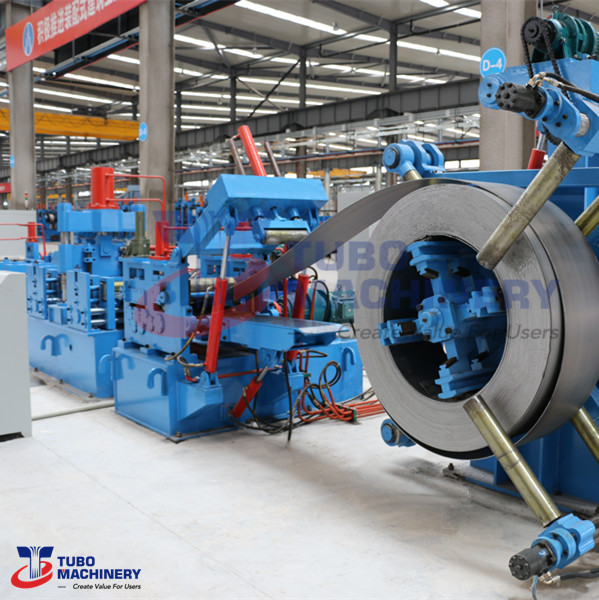

Cut To Length - China Manufacturers, Factory, Suppliers

Assume full responsibility to satisfy all needs of our clients; achieve continual advancements by endorsing the expansion of our purchasers; turn into the final permanent cooperative partner of clientele and maximize the interests of clients for Cut To Length, 400kw High Frequency Welder, Tubo Machinery, 2” Tubemill,High Frequency Welder. Welcome to set up long-term relationship with us. Best Price For Good Quality in China. The product will supply to all over the world, such as Europe, America, Australia,Pretoria, Lithuania,Hongkong, Berlin.Our solutions have national accreditation requirements for qualified, good quality items, affordable value, was welcomed by individuals all over the world. Our goods will continue to improve inside the order and appear forward to cooperation with you, Really should any of those items be of interest to you, please letus know. We will be satisfied to provide you a quotation up on receipt of the detailed needs.

Related Products