Reliable Supplier Jco Production Line - Orbital Milling Saw – TUBO Detail:

Product Description

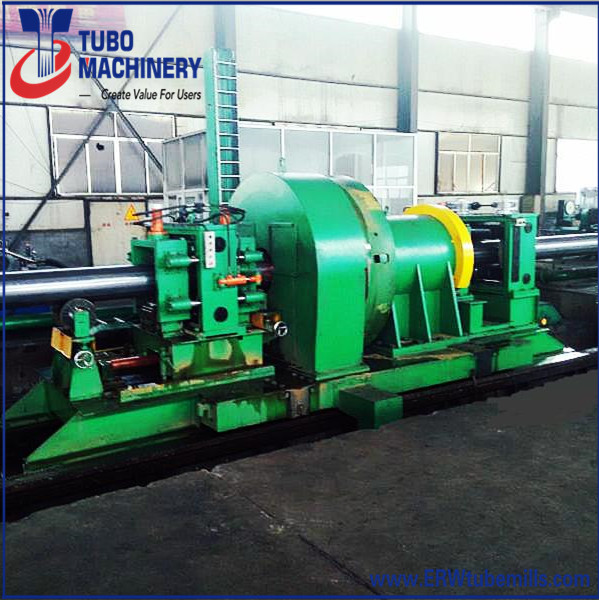

The orbital flying saw is mainly used for thick steel pipes with large diameters, and is applicable to different shapes and materials, such as round pipes, square pipes, profile pipes and more.

Advantage

1.automatically controlled (manual functions are available)

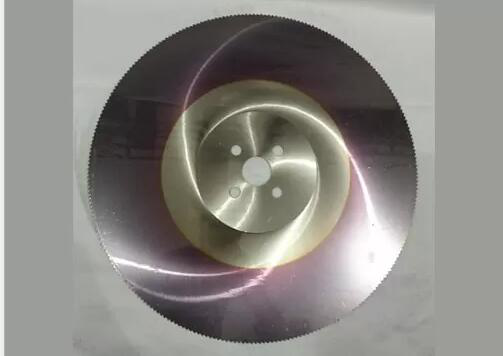

2.uses double milling cutter rotary cold cutting technology

3.The final cut is smooth and burr free, eliminating secondary deburring processes

4. saving money and labor.

Specification

|

Orbital Milling Saw |

|

|

Tube Diameter |

60~660mm |

|

Thickness |

2.5~22mm |

|

Working Speed |

30~50m/min |

Product detail pictures:

Related Product Guide:

Trustworthy good quality and excellent credit score standing are our principles, which will help us at a top-ranking position. Adhering towards the tenet of "quality first, buyer supreme" for Reliable Supplier Jco Production Line - Orbital Milling Saw – TUBO , The product will supply to all over the world, such as: Spain, Guinea, South Korea, We have a strict and complete quality control system, which ensures that each product can meet quality requirements of customers. Besides, all of our products have been strictly inspected before shipment.

1. Q : Are you manufacturer ?

A: Yes, We are manufacturer . More than 15 years R&D and Manufacturing Experience. We use more than 130 CNC machining equipments to guarantee our products perfect.

2. Q: What payment terms do you accept?

A: We are flexible on payment terms, please contact us for details.

3. Q:What information do you need to supply a quotation?

A: 1. Maximum Yield Strength of the material,

2.All pipe sizes needed (in mm),

3. Wall thickness (min-max)

4. Q: What is your advantages?

A: 1. Advanced mould share-use technology (FFX, Direct Forming Square). It saves a lot of invest amount.

2. Latest quick change technology to increase the output and reduce labor intensity.

3. More than 15 years R&D and Manufacturing Experience.

4. 130 CNC machining equipments to guarantee our products perfect.

5. Customized According to Customer Requirements.

5. Q: Do you have after sales support?

A: Yes,we have. We have a 10-person -professional and strong installation team.

6.Q: How about your service?

A:(1) One year’s warranty.

(2) Providing spare parts for life time at cost price.

(3) Providing Video technical support, Field installation, commissioning and training, online support, Engineers available to service machinery overseas.

(4) Provide technical service for facility reforming, refurbishment.

Superb technology, perfect after-sales service and efficient work efficiency, we think this is our best choice.