professional factory for Pipe Making Machine - Automatic Packing Machine – TUBO Detail:

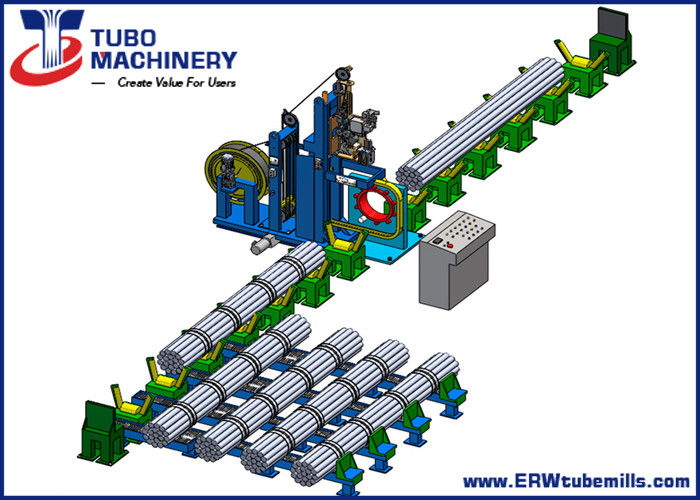

Steel Tube & Pipe Automatic packing Machine:

Automatic Stacking and Bundling Machine

Automatic packing machine is used to collect, stack steel pipe into 6 or 4 angles, and bundle automatically. It runs stably without manual operation. Meanwhile, eliminate the noise and knocking of shock of steel pipes. Our packing line can improve your pipes quality and production efficiency, reduce cost, as well as eliminate potential safety hazard.

Advantage

1.Stacking and Packing AUTOMATICALLY.

2.Perfect surface tube.

3.Less labors, Lower working strength.

4.Automatic operation, lower noisy.

Working procedure

The pipes are transported to the packing area by the run-out table:

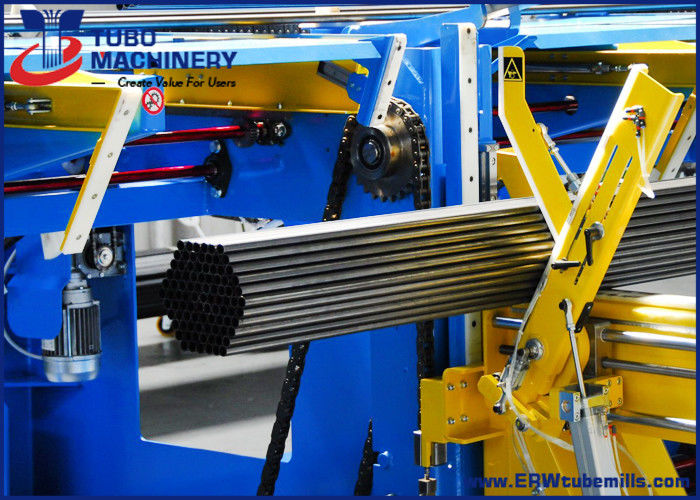

1.Pipes turning to packing machine

The pipes will be turned to the packing machine chain transportation device by the pipe turning device and then moved to the pipe counting position;

2.Pipe counting and stacking

The system has the set program that how many pieces of pipes will needed in a bundle for different sizes,then the system will send order to the machine counting and accumulating the pipes layer by layer until enough pipes are collected;the pipe collecting device will go down the height of one layer when one layer of pipes are collected and pushed to the collecting device;there is also one end alignment device at one end;

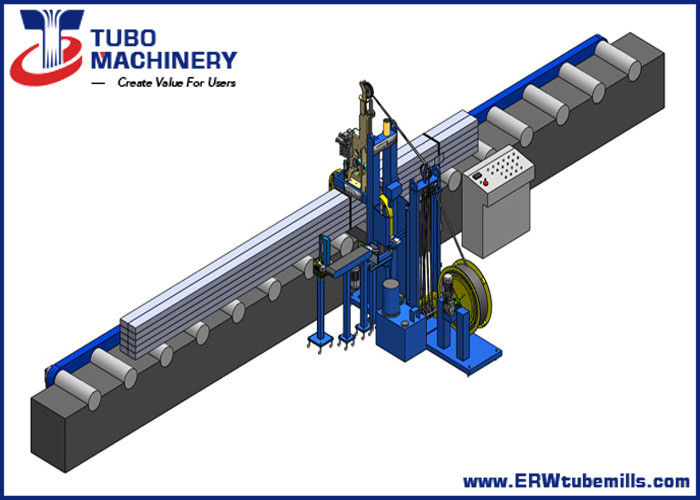

3.Bundle transportation

The whole bundle of pipes will be moved to the bundling position by the transporting car,then the collecting device will return to the collecting position waiting for a new bundle;

4.Automatic bundling device

The hanging automatic bundling device will work as the set bundling belt position requirement step by step; the progress are: the bundling machine will move down to the bundling position and contact the top layer of pipes, the belt guiding channel will close, the bundling head will send out the belt, connecting the belt end, then tightening the belt , buckling and then cut the belt; after that the belt guiding channel will open, the bundling head will return to the original position and preparing the next bundling;

The bundled pipes will be transported to the storing position by the storing chain transporting device, the transporting car will return and waiting for the next bundle;

5.Storing

The storing area will store three bundles and will be moved to the finished pipes area by the crane;

Cycling : the whole process will be controlled by the industrial PLC automatically, also has the function of manual and automatic control to guarantee the continuous production and working durability;

Company Introduction

Hebei Tubo Machinery Co.,LTD is a high-tech enterprise registered in Shijiazhuang City. Hebei Province. It specialized in Developing and Manufacturing for the complete set of equipments and related technical service of High Frequency Welded Pipe Production Line and Large-size Square Tube Cold Forming Line .

Hebei Tubo Machinery Co.,LTD With more than 130 sets all types of CNC machining equipment, Hebei Tubo Machinery Co.,Ltd., manufactures and exported to over 15 countries of welded tube/pipe mill, cold roll forming machine and slitting line, as well as auxiliary equipment for more than 15 years.

TUBO Machinery, as a partner of users, provides not only high precision machine products, but also technical support everywhere & anytime.

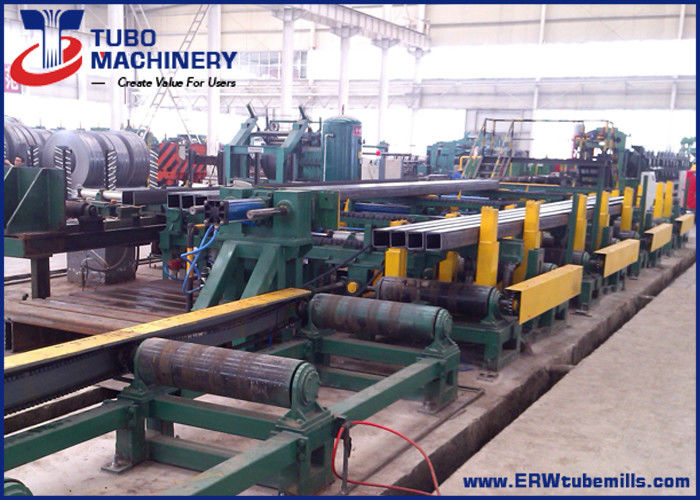

Our Workshopn

Our Certificate

Field Visits

Our advantage

Packing&shipping

Company Introduction

Hebei Tubo Machinery Co.,LTD is a high-tech enterprise registered in Shijiazhuang City. Hebei Province. It specialized in Developing and Manufacturing for the complete set of equipments and related technical service of High Frequency Welded Pipe Production Line and Large-size Square Tube Cold Forming Line .

Hebei Tubo Machinery Co.,LTD With more than 130 sets all types of CNC machining equipment, Hebei Tubo Machinery Co.,Ltd., manufactures and exported to over 15 countries of welded tube/pipe mill, cold roll forming machine and slitting line, as well as auxiliary equipment for more than 15 years.

TUBO Machinery, as a partner of users, provides not only high precision machine products, but also technical support everywhere & anytime.

Our Workshop

Our Certificate

Field Visits

Our advantage

Packing&shipping

Product detail pictures:

Related Product Guide:

We now have several exceptional workers customers good at marketing, QC, and working with types of troublesome trouble during the creation system for professional factory for Pipe Making Machine - Automatic Packing Machine – TUBO , The product will supply to all over the world, such as: luzern, Nigeria, Sudan, We supply skilled service, prompt reply, timely delivery, excellent quality and best price to our customers. Satisfaction and good credit to every customer is our priority. We focus on every detail of order processing for customers till they have received safe and sound items with good logistics service and economical cost. Depending on this, our products and solutions are sold very well in the countries in Africa, the Mid-East and Southeast Asia. Adhering to the business philosophy of ??customer first, forge ahead', we sincerely welcome clients from at home and abroad to cooperate with us.

1. Q : Are you manufacturer ?

A: Yes, We are manufacturer . More than 15 years R&D and Manufacturing Experience. We use more than 130 CNC machining equipments to guarantee our products perfect.

2. Q: What payment terms do you accept?

A: We are flexible on payment terms, please contact us for details.

3. Q:What information do you need to supply a quotation?

A: 1. Maximum Yield Strength of the material,

2.All pipe sizes needed (in mm),

3. Wall thickness (min-max)

4. Q: What is your advantages?

A: 1. Advanced mould share-use technology (FFX, Direct Forming Square). It saves a lot of invest amount.

2. Latest quick change technology to increase the output and reduce labor intensity.

3. More than 15 years R&D and Manufacturing Experience.

4. 130 CNC machining equipments to guarantee our products perfect.

5. Customized According to Customer Requirements.

5. Q: Do you have after sales support?

A: Yes,we have. We have a 10-person -professional and strong installation team.

6.Q: How about your service?

A:(1) One year’s warranty.

(2) Providing spare parts for life time at cost price.

(3) Providing Video technical support, Field installation, commissioning and training, online support, Engineers available to service machinery overseas.

(4) Provide technical service for facility reforming, refurbishment.

The goods we received and the sample sales staff display to us have the same quality, it is really a creditable manufacturer.