2″ Stainless Steel Pipe Making Machine - Factory, Suppliers, Manufacturers from China

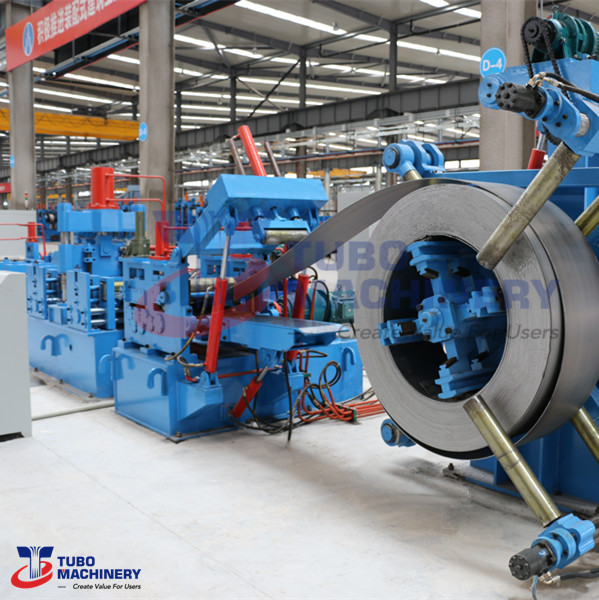

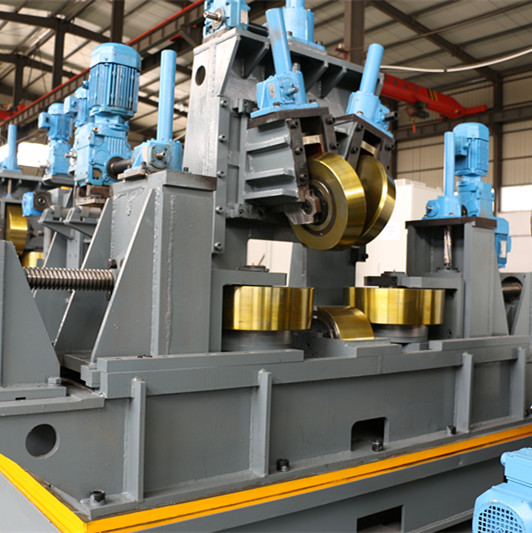

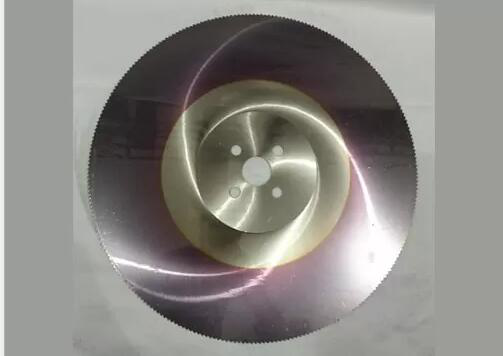

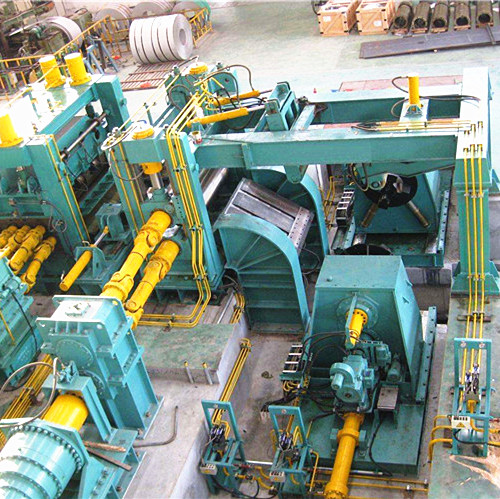

To meet the customers' over-expected satisfaction , we have our strong team to provide our best overall service which includes marketing, sales, designing, production, quality controlling, packing, warehousing and logistics for 2″ Stainless Steel Pipe Making Machine, 1-1/4” H.F.W Tube Mill, Jcoe Pipeline, 14” Iron Pipe Making Machine,Pipe Sawing Machine. In addition, we would properly tutorial the purchasers about the application techniques to adopt our items plus the way to select appropriate materials. The product will supply to all over the world, such as Europe, America, Australia,Bogota, Slovenia,Netherlands, Florence.We mainly sell in wholesale, with the most popular and easy ways of making payment, which are paying via Money Gram, Western Union, Bank Transfer and Paypal. For any further talk, just feel free to contact our salesmen, who are really good and knowledgeable about our prodcuts.

Related Products